Welcome to Our Company

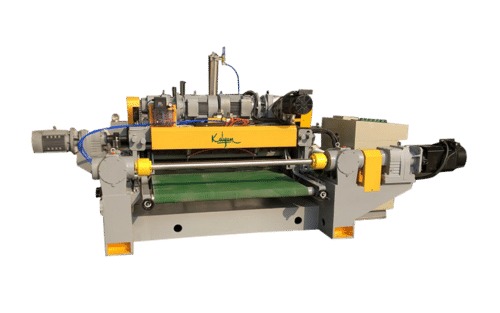

Two Head Wide Belt Sanding Machine

Product Details:

- Type Wide Belt Sanding Machine

- Material Heavy Duty Steel

- Capacity 800-1200 mm working width

- Computerized No

- Automatic Grade Automatic

- Power 15+11 kW (Main Motors)

- Voltage 380V / 50Hz

- Click to View more

Two Head Wide Belt Sanding Machine Price And Quantity

- 1 Box

Two Head Wide Belt Sanding Machine Product Specifications

- 3000 kg (Approx.)

- Wide Belt Sanding Machine

- 2 (Sanding Heads)

- No

- 0.6 MPa

- 800-1200 mm working width

- Heavy Duty Steel

- Standard White & Blue

- 15+11 kW (Main Motors)

- Automatic

- 2300 x 2200 x 2200 mm

- 380V / 50Hz

Two Head Wide Belt Sanding Machine Trade Information

- 100 Box Per Month

- 1 Months

Product Description

Specifications:

| MODEL | KI-1300-RP-RP-B-B |

| Width of Panel | 40-1300mm |

| Thickness of Sanded Panel | 3~160mm |

| Speed of Abrasive Belt on 1st Unit | 18 m/s |

| Speed of Abrasive Belt on 2nd Unit | 12 m/s |

| Speed of Conveyor Belt / Feed Speed | 6~30 m/min |

| Size of Abrasive Belt | 1330x2620 mm |

| Motor Required | 1st Head 20 / 25 H.P. |

| | 2nd Head 20 / 25 H.P |

| Brushing Unit | 7.5 H.P |

| Brushing Unit | 7.5 H.P |

| Feed Motor | 5 H.P. |

| Hoist Motor | 0.5 H.P. |

| Working Pressure | 0.55 Mpa |

| Consumption of Compressed Air | 1.56m3/ h |

| Volume of sucked air | 7896m3/h |

| Average Speed of Sucked Air | 25~30 m/s |

| Overall Dimensions (LxWxH) | 2600x3400x2750 mm |

| Weight | 4500 Kgs. |

All specifications, dimensions & design characteristic are subject to change without prior notice.

Advanced Sanding Performance

Designed for professional woodworkers and industries, this wide belt sanding machine combines high efficiency with great flexibility. Its dual sanding heads enable both calibration and fine sanding processes, delivering superior surface smoothness. The adjustable conveyor speed makes it suitable for different wood types and finishes, while the large working capacity accommodates panels commonly used in furniture and cabinetry.

Safety and Ease of Use

With a focus on operator protection, the machine integrates both overload and emergency stop systems. The digital thickness controller allows precise adjustments, minimizing errors and facilitating a streamlined workflow. Maintenance is simple due to its sturdy build and accessible components, making it ideal for regular, high-volume use.

Dust Collection and Workplace Environment

Maintaining a clean and safe work area is vital. The machine is equipped with three 150 mm diameter dust ports, efficiently capturing sanding residues. Combined with a noise level of under 80 dB, it promotes healthier conditions, reducing risks associated with wood dust inhalation while ensuring minimal disruption in shared workspace environments.

FAQs of Two Head Wide Belt Sanding Machine:

Q: How does the Two Head Wide Belt Sanding Machine operate for calibration and fine sanding?

A: The machine employs dual sanding heads and an adjustable conveyor speed (525 m/min). It first calibrates wood panels to the desired thickness and then uses fine sanding for a smooth finish. The digital thickness controller allows precise adjustments throughout the process.Q: What types of wood panels are suitable for this sanding machine?

A: This machine is designed for panels with a working width of 8001200 mm, thickness up to 100 mm, and minimum length of 500 mm. It is ideal for a range of applications such as furniture components, doors, and cabinetry.Q: When should I use the overload and emergency stop systems?

A: The overload and emergency stop features should be activated if the machine detects excessive strain, overheating, or any immediate safety risks during operation. These systems protect both operators and the equipment from accidents or damage.Q: Where is the machine manufactured or supplied from?

A: This wide belt sanding machine is available from exporters, importers, manufacturers, suppliers, and traders based in India. It conforms to Indian industrial standards and comes in standard white and blue coloring.Q: What is the maintenance process for this sanding machine?

A: Routine maintenance includes checking motor performance, ensuring the sanding belts are properly aligned and replaced when needed, emptying dust collection units, and inspecting safety features. Regular servicing maximizes lifetime and safe operation.Q: How does the dust collection system benefit users during sanding operations?

A: The three 150 mm ports efficiently extract sanding debris, minimizing airborne dust. This not only keeps the workspace cleaner but also improves air quality and operator health, while reducing maintenance caused by dust accumulation.Q: What are the advantages of the digital thickness controller on this machine?

A: The digital thickness controller supports precise panel adjustment, reducing manual measurement errors and increasing accuracy. This results in consistent sanding outcomes, greater productivity, and less material wastage.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Plywood Making Machines' category

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free