Welcome to Our Company

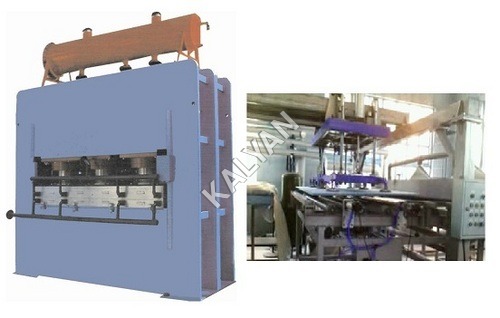

Short Cycle Press (SCP-1600-96)

Product Details:

- Product Type Short Cycle Press

- Power Source Electricity

- Operating Type Automatic

- Surface Treatment Painted

- Color White

- Usage & Applications Industrial

- Click to View more

Short Cycle Press (SCP-1600-96) Price And Quantity

- 1 Inch

Short Cycle Press (SCP-1600-96) Product Specifications

- White

- Painted

- Automatic

- Industrial

- Electricity

- Short Cycle Press

Short Cycle Press (SCP-1600-96) Trade Information

- 100 Inch Per Month

- 1 Months

Product Description

Short Cycle Single Day Light Press Model SCP-1600-96

With Auto feeding table/ Conveyor only. The machine is complete with power pack & electric control panel including out feed table/ conveyor having vacuum suction pad in the front enable to such and to take the panel out of the press. All electrical components such as MCB, Relays/ Contactors etc. are of "Siemens/ Schneider" make. PLC is of "Mitsubishi" make.

Hanging Type Vacuum Lifter

Specification :

| MODEL | SCP-1600-96 |

| Total Pressure | 16000 KN |

| Board Feeding ways | 9 Feet Length wise |

| Upper Platen dimension | 1940x2900x160mm |

| Lower Platen dimension | 1940x2900x120mm |

| Opening of Platen | >= 200mm |

| Board Pressing Area | 1830x2750mm |

| No. of Cylinders / Diameter | 8nos.xf320x200mm stoke |

| Lifting Cylinder | 4 Nos. / 80x50x200 mm |

| Pressure of Lifting Cylinder | 9-12 Mpa |

| Board Loading Time | <=5 sec. |

| Non Working Closing Time | <=2.5, 3 sec. |

| Working Closing Time | < = 3-5 sec. |

| Board Lamination Time | 20-35 sec. |

| Opening and Unloading Time | 6 sec. |

| Total cycle time | 45 - 50 second |

| Structural Configuration | Welded Frame |

| Thickness of Steel Frame | 65mm |

| Pump | Shanghai (China Make) |

| Make of Hydraulic Valves | Japan |

| Temperature of Platen | 180-2200C |

| IN feed Table | PLC Controlled (Mistubishi Make) |

| Out Feeding Table | Vacuum Type - Maximum Load Lifting Capacity 80 Kg. |

| Total Power | 22 + 0.75 + 0.75 KW |

| Weight | About 45 Tons |

| Work Temperature | 180-200 + 1o can be set through the temperature meter. |

All specifications, dimensions & design characteristic shown in the catalogues are subject to change without prior notice

Advanced Surface Treatment Technology

The SCP-1600-96 utilizes state-of-the-art technology to achieve consistent and high-quality painted finishes on various substrates. Its automatic operation ensures precise control and repeatability, making it a valuable asset for industrial applications where uniform surface treatment is essential.

Reliable Industrial Performance

Engineered for continuous operation, this short cycle press delivers superior reliability under demanding conditions. The combination of automatic controls and an efficient electric power source contributes to rapid throughput and consistent product quality, helping manufacturers meet stringent industrial standards.

FAQs of Short Cycle Press (SCP-1600-96):

Q: How does the SCP-1600-96 Short Cycle Press enhance industrial surface treatment processes?

A: The SCP-1600-96 optimizes surface treatment by delivering uniform, high-quality painted finishes through precise automatic controls. Its short cycle operation enables rapid processing, reducing downtime and improving production efficiency for industrial applications.Q: What is the primary usage of the SCP-1600-96 in industrial settings?

A: This automatic short cycle press is mainly used for applying painted surface treatments to wood panels, laminates, and similar materials, supporting industries such as furniture manufacturing and decorative surfaces.Q: When is the SCP-1600-96 most beneficial during manufacturing operations?

A: The SCP-1600-96 is most beneficial during high-volume processing stages where consistent surface quality and swift turnaround are critical, maximizing productivity and helping meet tight delivery deadlines.Q: Where can the SCP-1600-96 be installed and used effectively?

A: The press is designed for installation in industrial environments such as factories and large-scale production units where its robust construction and automatic operation can be leveraged for efficient workflow.Q: What is the surface treatment process facilitated by the SCP-1600-96?

A: It utilizes an automated system powered by electricity to apply a uniform painted finish to panels. The process is rapid and repeatable, ensuring every batch meets required quality standards.Q: What advantages does the automatic operating type of the SCP-1600-96 offer?

A: Automatic operation minimizes human intervention, reduces errors, accelerates production cycles, and ensures consistent results, which ultimately leads to improved efficiency and cost savings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free