Welcome to Our Company

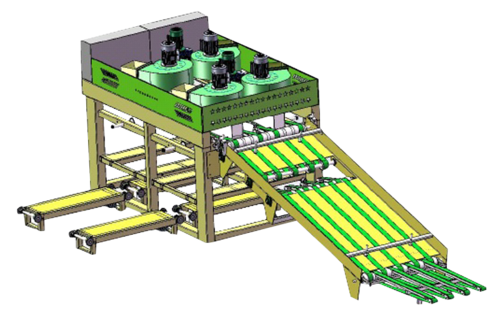

VACUUM STACKER

Product Details:

- Type Vacuum Stacker

- Material Mild Steel

- Capacity 2000 Kg/Hr

- Computerized No

- Automatic Grade Automatic

- Power 3 HP

- Voltage 380 V

- Click to View more

X

VACUUM STACKER Price And Quantity

- 1 , , Box

VACUUM STACKER Product Specifications

- Automatic

- No

- Vacuum Stacker

- 380 V

- 6 Bar

- Mild Steel

- 3 HP

- 2000 Kg/Hr

- 950 Kg

- 2200 x 1200 x 1700 mm

- Blue

VACUUM STACKER Trade Information

- 100 , , Box Per Month

- 1 Months

Product Description

Vacuum stacker (china make)- With conveyor

- To be fitted after the spindle less machine

Specifications:

|

Stack Veneer Size |

400 to 2600 mm |

|

Thickness |

0.3 to 3mm |

|

Speed |

45 to 110 m/min |

|

Fan Motors |

7.5kw x 4 Nos |

|

Conveyor Motor |

4 kw x 2 Nos |

|

Lifting Motor |

7.5 kw |

All specifications,dimensions & design characteristic are subject to change without prior notice.

Versatile Sheet Handling for Modern Industries

Designed for packaging and printing sectors, the Vacuum Stacker streamlines continuous stacking and destacking processes. Automation via PLC control delivers precision and flexibility, handling various sheet dimensions efficiently. Its blue, powder-coated mild steel frame ensures both resilience and style for demanding industrial environments.

Safety, Efficiency, and User-Friendly Operation

The system prioritizes safety with an integrated emergency stop and overload protection. Adjustable feeding speed, up to 30 meters per minute, allows for customization based on specific operational needs. Despite its powerful 3 HP drive, the stacker maintains a low noise profile, creating a more comfortable workspace.

FAQs of VACUUM STACKER:

Q: How does the Vacuum Stacker operate for continuous sheet handling?

A: The Vacuum Stacker utilizes an automatic, PLC-controlled system to continuously stack or destack sheets. Sheets are transported on an 1100 mm wide conveyor belt, where they are handled by a vacuum system powered by either a Venturi or electric generator. This ensures consistent alignment and rapid movement, enabling efficient workflow.Q: What are the main benefits of using this Vacuum Stacker in the packaging and printing industry?

A: Key benefits include enhanced automation for high-speed operations, precise stacking up to 1200 mm in height, and capacity to handle 2000 Kg/hr. Its safety features reduce workplace accidents, and the machines quiet operation improves working conditions. It also minimizes manual handling, reducing labor costs and errors.Q: When is it advisable to utilize the Vacuum Stacker in workflow processes?

A: The Vacuum Stacker is best used when there is a need for uninterrupted, high-efficiency sheet handling, especially in high-volume packaging and printing operations. It is most effective during tasks requiring consistent stacking or destacking over extended production cycles.Q: Where can this Vacuum Stacker be installed and operated?

A: This machine is suitable for installation in industrial environments such as packaging plants, commercial print works, and sheet handling facilities across India. Its robust build and manageable dimensions make it adaptable to various production setups.Q: What types of safety mechanisms does the Vacuum Stacker incorporate?

A: The Vacuum Stacker includes advanced safety features like an emergency stop button and overload protection to safeguard operators and prevent equipment damage during use.Q: How is the feeding speed controlled and adjusted on this Vacuum Stacker?

A: Feeding speed is adjustable via the PLC control system, allowing operators to set speeds up to 30 meters per minute depending on the material type and desired throughput.Q: What is the process for maintaining the Vacuum Stacker?

A: Routine maintenance involves checking the condition of the conveyor belt, monitoring the vacuum generator (Venturi or electric), and ensuring the steel frames integrity. Regular inspection of the emergency stop and overload mechanisms is recommended to maintain operational safety.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Plywood Making Machines' category

Send Inquiry

Send Inquiry Send SMS

Send SMS