Welcome to Our Company

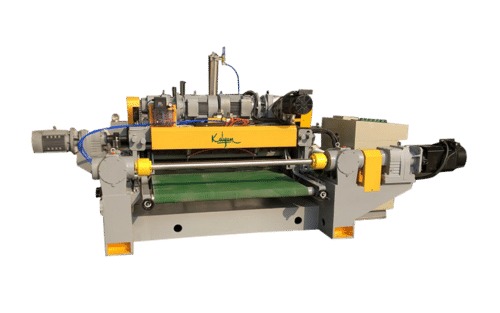

Heavy Duty High Speed Spindleless

Product Details:

- Type Heavy Duty High Speed Spindleless

- Material Cast Iron, Steel

- Capacity High Production Efficiency

- Computerized Yes

- Automatic Grade Automatic

- Power 12-18 kW

- Voltage 380V / 415V, 3 Phase

- Click to View more

X

Heavy Duty High Speed Spindleless Price And Quantity

- 1 Box

Heavy Duty High Speed Spindleless Product Specifications

- 4200 mm x 2200 mm x 1800 mm

- 380V / 415V, 3 Phase

- Automatic

- 12-18 kW

- 5000 Kg (approx.)

- 0.6-0.8 MPa

- Cast Iron, Steel

- Blue & Yellow

- Yes

- High Production Efficiency

- Heavy Duty High Speed Spindleless

Heavy Duty High Speed Spindleless Trade Information

- 100 Box Per Month

- 1 Months

Product Description

Specifications:

|

Max. Cutting Length |

2700 mm |

|

Max. Cutting Diameter |

500mm |

|

Remaining Diameter (Left over Roller) |

30~35 mm |

|

Cutting Thickness |

0.28 - 3 mm (0.2 - 3 mm - optional) |

|

Outfeed Speed |

36m/min (42 m/min - Optional) |

|

Feeding Motor |

15 HP |

|

Drive Motor for Pressure Bar Rollers (Rotary Nose Bar) |

10hp x 2 = 20 HP |

|

Roller Drive Motors (Double Rollers) |

15hp x 2 = 30 HP |

|

Weight |

8500 Kgs. |

All specifications, dimensions & design characteristic are subject to change without prior notice.

Unmatched Performance for Veneer Manufacturing

This spindleless peeler is engineered for high-speed, heavy-duty operation in veneer and plywood production environments. Its gear drive system and hydraulic core drive enable smooth log rotation while the water cooling system maintains optimal temperatures. Advanced PLC control ensures precision, while a noise level below 75 dB allows for a safer workplace.

Versatile and Efficient Design

Handling logs with diameters from 80 mm to 500 mm and lengths up to 1300 mm, the machine adapts to various timber sizes, boosting production flexibility. Automatic operation and computerized controls reduce manual intervention, improving accuracy and throughput in mass manufacturing.

FAQs of Heavy Duty High Speed Spindleless:

Q: How does the spindleless machine handle different log sizes?

A: This equipment accommodates logs with diameters ranging from 80 mm to 500 mm and up to 1300 mm in length, providing flexibility for various wood types and optimizing yield in plywood and veneer production.Q: What is the process for peeling logs in this machine?

A: Logs are automatically fed and securely held without spindles. As they rotate using the hydraulic core drive and gear transmission, the 1500 mm blade precisely peels high-quality veneer sheets at speeds from 40 to 100 meters per minute under PLC control.Q: When should the water cooling system be used?

A: The water cooling system is essential during extended, high-speed operations to maintain optimal blade and component temperatures. This prevents overheating, thus extending the machines lifespan and maintaining performance.Q: Where is this spindleless peeler typically used?

A: It is widely used in veneer and plywood manufacturing plants, especially where fast, high-volume log processing is required. Exporters, manufacturers, suppliers, and traders in India utilize this machine for industrial-scale wood panel production.Q: What are the main benefits of using this equipment?

A: Key advantages include high production efficiency, minimized labor due to automation, precision cutting, and consistent veneer quality. The machines low noise and robust build also contribute to improved workplace safety and long-term reliability.Q: How is the machine operated and controlled?

A: With a computerized, automatic system governed by a PLC-based control panel, operators can easily adjust peeling speed, monitor operations, and ensure optimal performance with minimal manual input.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Plywood Making Machines' category

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free