Welcome to Our Company

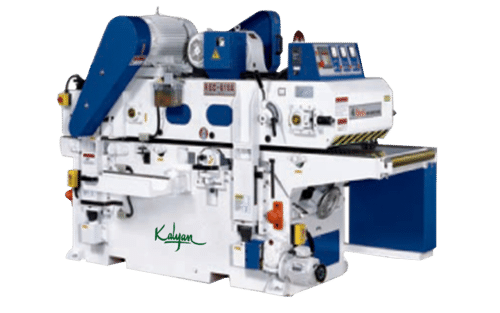

Two Head Wide Belt Sanding Machine

Product Details:

- Type Two Head Wide Belt Sanding Machine

- Material Heavy Duty Steel

- Capacity High Production (up to 1000 mm width)

- Computerized No

- Automatic Grade Automatic

- Power 33 kW (Main Motors)

- Voltage 380V / 415V, 3 Phase

- Click to View more

X

Two Head Wide Belt Sanding Machine Price And Quantity

- 1 Box

Two Head Wide Belt Sanding Machine Product Specifications

- 2200 mm x 2100 mm x 2100 mm

- 380V / 415V, 3 Phase

- 33 kW (Main Motors)

- High Production (up to 1000 mm width)

- No

- White & Blue

- 0.6 MPa

- Automatic

- Two Head Wide Belt Sanding Machine

- Approx. 3000 kg

- Heavy Duty Steel

Two Head Wide Belt Sanding Machine Trade Information

- 100 Box Per Month

- 1 Months

Product Description

Specifications:

| MODEL | KI-1300-R-RP |

| Width of Panel | 40-1300mm |

| Thickness of Sanded Panel | 3~160mm |

| Speed of Abrasive Belt on 1st Unit | 18m/s |

| Speed of Abrasive Belt on 2nd Unit | 12 m/s |

| Speed of Conveyor Belt / Feed Speed | 6~30 m/min |

| Size of Abrasive Belt | 1320x2620 mm |

| Motor Required | 1st Head 30 HP |

| | 2nd Head 25 HP |

| Feed Motor | 5 HP |

| Hoist Motor | 0.5 HP |

| Vacuum fan motor | 7.5 HP |

| Working Pressure | 0.55 Mpa |

| Consumption of Compressed Air | 1.56m3/ h |

| Volume of sucked air | 7896m3/h |

| Average Speed of Sucked Air | 25~30 m/s |

| Overall Dimensions (LxWxH) | 2600x2800x2750mm |

| Weight | 3600 Kgs. |

All specifications, dimensions & design characteristic are subject to change without prior notice.

Versatile Sanding Applications

This machine is capable of sanding various materials including plywood, MDF, solid wood, and veneers. Its wide working range of 3110 mm thickness and up to 1300 mm width accommodates a broad spectrum of panel sizes and types, making it ideal for many furniture manufacturers and wood processing industries.

High Production Efficiency

Engineered for high productivity, the two sanding heads and powerful main drive motors enable the machine to process workpieces rapidly and with uniform results. Adjustable feeding and abrasive belt speeds allow for customizable finishes on large production runs, reducing downtime and increasing throughput.

Robust Safety and Easy Operation

Safety is prioritized with features such as overload protection, emergency stops, and protective covers. The digital control panel streamlines operation and allows easy parameter adjustment while maintaining safe working conditions for operators.

FAQs of Two Head Wide Belt Sanding Machine:

Q: How does the Two Head Wide Belt Sanding Machine improve sanding efficiency?

A: The dual sanding heads allow for simultaneous, sequential sanding, which streamlines the process and achieves a smoother finish in a shorter time. Adjustable belt and feeding speeds also enable optimization for different material requirements.Q: What types of materials can this machine sand?

A: It can sand plywood, MDF, solid wood, and veneer panels with consistent results across a wide range of thicknesses (3110 mm).Q: When should I adjust the feeding speed and abrasive belt speed?

A: Adjust speed settings based on the material type, grain size, and desired surface quality. Softer woods or finer finishes may require slower speeds for optimal results, while harder materials can often be processed at higher speeds.Q: Where is this sanding machine commonly used?

A: Its widely used in furniture manufacturing, woodworking factories, panel processing plants, and by traders, exporters, and importers across India.Q: What safety features are included in this machine?

A: For operator safety, the machine incorporates overload protection, emergency stop controls, and protective covers to prevent accidental contact with moving parts.Q: How do I maintain this machine for optimal performance?

A: Regularly clean the machine, inspect abrasive belts for wear, empty dust collection ports, and check that all safety features and emergency stops remain operational. Scheduled maintenance prolongs service life and performance reliability.Q: What are the main benefits of using this wide belt sanding machine?

A: Its key benefits are high production capacity, precise and uniform sanding, robust safety features, and suitability for a variety of wood and composite materials, helping businesses improve quality and increase output.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Plywood Making Machines' category

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free