Welcome to Our Company

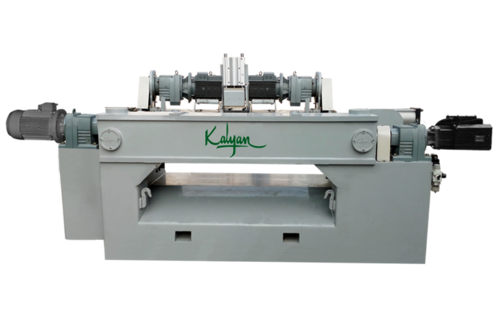

HIGH SPEED HEAVY DUTY SPINDLELESS ROTARY PEELING MACHINE (1300-BDW)

Product Details:

- Type Spindleless Rotary Peeling Machine

- Material Heavy Duty Steel Structure

- Capacity Up to 120 m/min

- Computerized Yes

- Automatic Grade Fully Automatic

- Power 38 kW

- Voltage 380V / 415V

- Click to View more

X

HIGH SPEED HEAVY DUTY SPINDLELESS ROTARY PEELING MACHINE (1300-BDW) Price And Quantity

- 1 Box

- Double Roller, Gear Driven

- Variable (Frequency Controlled)

- Emergency Stop, Safety Covers

- Heavy Duty, High Efficiency

- 150 mm x 140 mm x 16 mm

- 500 mm

- Plywood and Veneer Production Lines

- 0.5 mm - 3.5 mm

- <85 dB(A)

- 32 mm

- Heat Treated Alloy Steel

- PLC Touch Screen

- 1300 mm

HIGH SPEED HEAVY DUTY SPINDLELESS ROTARY PEELING MACHINE (1300-BDW) Product Specifications

- 5400 mm x 2200 mm x 1600 mm

- Spindleless Rotary Peeling Machine

- Standard Industrial Green

- Heavy Duty Steel Structure

- 0.6-0.8 MPa

- Approx. 7000 kg

- Yes

- 38 kW

- 380V / 415V

- Up to 120 m/min

- Fully Automatic

- Double Roller, Gear Driven

- Variable (Frequency Controlled)

- Emergency Stop, Safety Covers

- Heavy Duty, High Efficiency

- 150 mm x 140 mm x 16 mm

- 500 mm

- Plywood and Veneer Production Lines

- 0.5 mm - 3.5 mm

- <85 dB(A)

- 32 mm

- Heat Treated Alloy Steel

- PLC Touch Screen

- 1300 mm

HIGH SPEED HEAVY DUTY SPINDLELESS ROTARY PEELING MACHINE (1300-BDW) Trade Information

- 100 Box Per Month

- 1 Months

Product Description

https://studio.youtube.com/video/ZMyAzSuXAnw/edit

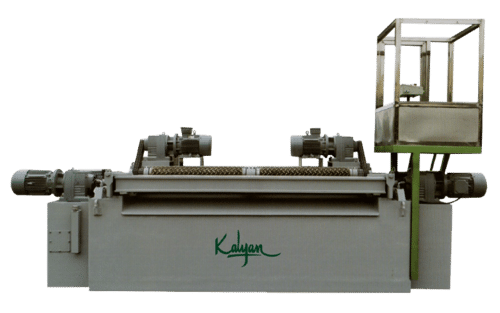

HIGH SPEED HEAVY DUTY SPINDLELESS ROTARY PEELING MACHINE MODEL HAVING TWO SPEEDS WITH SERVO MOTOR MODEL 1300-BDW

Complete with following features

- Can peel upto 500 mm diameter.

- Veneer outfeed two speed 45-100 m.min.

- Inbuilt clipper.

- Log Pusher for Centering.

- Log Punch System.

- Heavy Duty Gear Box.

- Servo Motor.

- Required Motors.

- Conveyor belt on the exit side - to take out the veneer after being cut in the required size by clipper.

Advanced Control and Precision

With a PLC touch screen and frequency-controlled variable feed speed, operators can easily adjust peeling thickness between 0.5 mm and 3.5 mm for optimal output. The computerized control system streamlines operations and increases dimensional consistency, making it ideal for high-volume production environments.

Superior Strength and Efficiency

Built from heavy duty steel and equipped with heat treated alloy steel rollers, the 1300-BDW is designed for longevity and reliable performance. Its double roller gear-driven transmission and heavy-duty motor enable continuous operation at high speed, supporting demanding production schedules.

Comprehensive Safety and User Features

Safety covers and emergency stop functions provide secure working conditions, while noise levels remain below 85 dB(A). The fully automatic grade minimizes manual intervention, supporting both efficiency and workplace safety in plywood and veneer factories.

FAQs of HIGH SPEED HEAVY DUTY SPINDLELESS ROTARY PEELING MACHINE (1300-BDW):

Q: How does the machine maintain high peeling accuracy and efficiency during operation?

A: The 1300-BDW uses a computerized PLC touch screen control system coupled with frequency-controlled variable feed speed, allowing operators to precisely adjust peeling thickness between 0.53.5 mm. Its gear-driven double roller transmission and robust 38 kW motor ensures consistent, high-speed operation up to 120 m/min without loss of quality.Q: What materials and log sizes can the spindleless rotary peeling machine handle?

A: This machine is designed for plywood and veneer production, accommodating logs up to 1300 mm in length and diameters ranging from 32 mm (min core) to 500 mm. The structure and rollers are made from heat treated alloy steel, providing durability for processing hardwood and softwood species.Q: When should the emergency stop or safety covers be used?

A: Safety features such as the emergency stop and safety covers are essential when performing maintenance, troubleshooting, or if unsafe conditions are detected during operation. These features help protect operators and prevent damage to the machine or processed material.Q: Where can this machine be integrated within a production line?

A: The 1300-BDW is suited for use in industrial plywood and veneer production lines. Its compact footprint and fully automatic operation make it ideal for integration between log preparation and sheet stacking stages, enhancing workflow and production rates.Q: What is the typical process for setting up and using the peeling machine?

A: Setup involves positioning the machine, connecting to power (380V/415V) and compressed air (0.6-0.8 MPa), and configuring parameters via the PLC touch screen. Once logs are loaded, the machine automatically peels veneers to desired thickness, with adjustable feed speed for optimal output.Q: How does the machine benefit exporters, importers, and manufacturers in India?

A: As a fully automatic, high-capacity rotary peeling solution, the 1300-BDW boosts production rates, improves veneer quality, and reduces labor costs. Its reliability and ease of operation support businesses in meeting domestic and export demands with consistent results.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

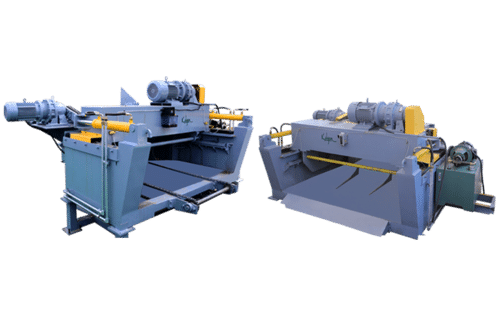

Other Products in 'Veneer Section' category

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free