Welcome to Our Company

FULLY AUTOMATIC PLC CONTROLLED L TYPE HIGH SPEED VENEER FINGER JOINT PANEL COMPOSER

Product Details:

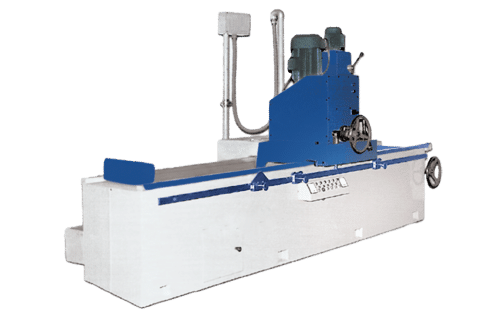

- Type Fully Automatic PLC Controlled L Type High Speed Veneer Finger Joint Panel Composer

- Material Heavy Duty Steel Structure

- Capacity Up to 12 panels/minute

- Computerized PLC Controlled

- Automatic Grade Fully Automatic

- Power 18 KW

- Voltage 380V / 50-60Hz

- Click to View more

X

FULLY AUTOMATIC PLC CONTROLLED L TYPE HIGH SPEED VENEER FINGER JOINT PANEL COMPOSER Price And Quantity

- 1 Millimeter

FULLY AUTOMATIC PLC CONTROLLED L TYPE HIGH SPEED VENEER FINGER JOINT PANEL COMPOSER Product Specifications

- Blue & Grey

- 18 KW

- Up to 12 panels/minute

- Fully Automatic

- 380V / 50-60Hz

- Heavy Duty Steel Structure

- 12000 mm x 2400 mm x 1850 mm

- Fully Automatic PLC Controlled L Type High Speed Veneer Finger Joint Panel Composer

- PLC Controlled

- Approx. 4500 kg

- 0.6-0.8 MPa

Product Description

Unlock the pinnacle of woodworking technology with the sought-after FULLY AUTOMATIC PLC CONTROLLED L TYPE HIGH SPEED VENEER FINGER JOINT PANEL COMPOSER. Meticulously crafted from heavy-duty steel, this laureate machine offers a noteworthy reduced operator requirement, allowing a single person to efficiently manage production. With automatic infeed and precision gluing, it handles panels up to 2500 mm in length and 50 mm in thickness at speeds reaching 12 panels per minute. The Siemens PLC touch screen system ensures effortless control, delivering reliable finger joint solutions for growing manufacturing operations. Purchase this top-tier solution to elevate productivity and safety in your facility.

Versatile Usage & Remarkable Advantages

This fully automatic L type veneer finger joint panel composer is used for producing superior finger joint panels with efficiency and consistency. Its advanced automation streamlines operations and reduces labor costs, making it a prime choice for manufacturers and woodworking plants. It is primarily sought-after for its high speed, noteworthy accuracy, and reduced manpower requirement. Used as essential equipment in producing stable, long-length panels, it unlocks competitive advantages for exporters, suppliers, and manufacturers in the woodworking industry.

Payment Terms, Secure Packaging & Global Export

Payment exchanges are flexible and designed for your business convenience, accommodating common international commerce terms. Shipped goods are securely packaged to withstand freight and handling, ensuring each unit arrives safely to its destination. The machine is primarily exported to markets in Asia and the Middle East, positioning it as a preferred choice among global importers and traders. Each shipment is meticulously prepped to minimize damage and maximize satisfaction upon delivery.

Versatile Usage & Remarkable Advantages

This fully automatic L type veneer finger joint panel composer is used for producing superior finger joint panels with efficiency and consistency. Its advanced automation streamlines operations and reduces labor costs, making it a prime choice for manufacturers and woodworking plants. It is primarily sought-after for its high speed, noteworthy accuracy, and reduced manpower requirement. Used as essential equipment in producing stable, long-length panels, it unlocks competitive advantages for exporters, suppliers, and manufacturers in the woodworking industry.

Payment Terms, Secure Packaging & Global Export

Payment exchanges are flexible and designed for your business convenience, accommodating common international commerce terms. Shipped goods are securely packaged to withstand freight and handling, ensuring each unit arrives safely to its destination. The machine is primarily exported to markets in Asia and the Middle East, positioning it as a preferred choice among global importers and traders. Each shipment is meticulously prepped to minimize damage and maximize satisfaction upon delivery.

FAQ's of FULLY AUTOMATIC PLC CONTROLLED L TYPE HIGH SPEED VENEER FINGER JOINT PANEL COMPOSER:

Q: How does the fully automatic PLC controlled veneer panel composer benefit my production line?

A: The machine streamlines panel joining operations with remarkable speed and precision, unlocking higher productivity while significantly reducing operator involvement to just one person.Q: What is the process for using this finger joint panel composer?

A: Simply load the panels onto the automatic infeed conveyor and the PLC system manages precise gluing, finger jointing, and panel assembly, all monitored via a Siemens touch screen interface.Q: Where is this veneer finger joint panel composer primarily used?

A: It is primarily used in woodworking manufacturing plants, exporting companies, and trading houses, especially by exporters, importers, and suppliers seeking efficient panel production.Q: What are the main safety features included with this machine?

A: The machine comes equipped with an emergency stop, safety guards, and overload protection to ensure safe operation at all times.Q: When can I expect the goods to be shipped after placing an order?

A: Shipping timelines depend on production schedules, but goods are generally packed and shipped promptly to ensure timely freight delivery, with export processing tailored to your location.Q: How is the machine packaged for export?

A: Each composer is shipped with robust packaging materials to prevent damage during freight transit, ensuring the machine reaches you in optimal condition.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Veneer Section' category

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free