Welcome to Our Company

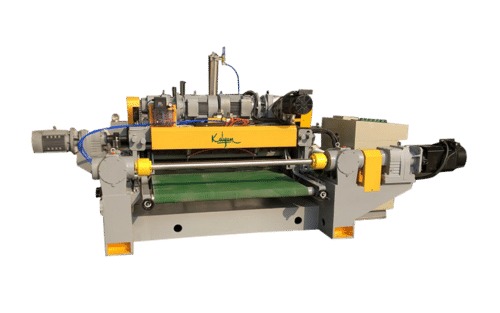

Two Head Wide Belt Sanding Machine

Product Details:

- Type Wide Belt Sanding Machine

- Material Heavy Duty Steel

- Capacity 800 mm working width

- Computerized No

- Automatic Grade Semi-Automatic

- Power 22 kW

- Voltage 380 V

- Click to View more

Two Head Wide Belt Sanding Machine Price And Quantity

- 1 Box

Two Head Wide Belt Sanding Machine Product Specifications

- 0.6 MPa

- 2200 kg

- Wide Belt Sanding Machine

- Heavy Duty Steel

- 380 V

- Semi-Automatic

- 22 kW

- 1900 x 2200 x 2100 mm

- Light Grey

- Two

- 800 mm working width

- No

Two Head Wide Belt Sanding Machine Trade Information

- 100 Box Per Month

- 1 Months

Product Description

TWO HEAD WIDE BELT SANDING MACHINE MODEL KI-1300-R-RP (HEAVY DUTY) (IMPORTED)

complete with Electric Control Panel and required motors having following features:

- Abrasive belt size 103 in length.

- 1st Head is capable of sanding having 30 hp. Motor.

- 2nd Head with contact roller and pad capable of calibrating / sanding and polishing of panel having 25 H.P. motor (optional 20 HP.)

- Variable speed unit.

- Cleaning & Polishing roller having 1 H.P.

- Microcomputer Controller.

- Jumping Air Pad

- Nozzle of air jet for cleaning of sanding belt.

- Thickness Measuring Unit or Automatic device for working thickness.

- Extension table in the infeed, having 3 extra rollers.

- Automatic centering of conveyor belt.

- Motorised lifting of the table.

- Emergency Stop.

- Ampere meter.

- Rubberised Pressing Rollers.

- Star Delta Start

- Belt Safety Emergency.

- Auto positioning of table.

- In case of emergency stop, table lowers automatically.

- Speed of Conveyor Belt / Feed Speed 6~30 m/min

- Vaccum Suction Conveyor Belt.

The Vaccum suction conveyor belt straightens warped panels and holds them securely on the table.

Cost of Compressor & Dust Collector unit (Including Air Bags, Dust Hood, Pipes) are not included in the machine.

Specifications:

| MODEL | KI-1300-R-RP |

| Width of Panel | 40-1300mm |

| Thickness of Sanded Panel | 3~160mm |

| Speed of Abrasive Belt on 1st Unit | 18m/s |

| Speed of Abrasive Belt on 2nd Unit | 12 m/s |

| Speed of Conveyor Belt / Feed Speed | 6~30 m/min |

| Size of Abrasive Belt | 1320x2620 mm |

| Motor Required | 1st Head 30 HP |

| | 2nd Head 25 HP |

| Feed Motor | 5 HP |

| Hoist Motor | 0.5 HP |

| Vacuum fan motor | 7.5 HP |

| Working Pressure | 0.55 Mpa |

| Consumption of Compressed Air | 1.56m3/ h |

| Volume of sucked air | 7896m3/h |

| Average Speed of Sucked Air | 25~30 m/s |

| Overall Dimensions (LxWxH) | 2600x2800x2750mm |

| Weight | 3600 Kgs. |

All specifications, dimensions & design characteristic are subject to change without prior notice.

Efficient Twin-Head Sanding Solution

This sanding machine utilizes two headsa drum and a padto ensure smooth, uniform surface finishing on panels and wooden furniture. The wide 800 mm working width supports both large and mid-sized workpieces, enhancing productivity for manufacturers and workshops. With adjustable conveyor speeds and a substantial main motor power, it easily adapts to different processing requirements while delivering consistent results.

Robust Build and User-Friendly Operation

Manufactured from heavy-duty steel, this semi-automatic sanding machine is engineered for longevity and stability. The feed table height is ergonomically set at 900 mm, supporting comfortable operation. Its intuitive controls allow quick adjustment of sanding parameters for various thicknesses and applications. The noise level remains below 85 dB, ensuring a safer, quieter workshop environment.

Quality Air Management and Clean Workspace

Fitted with a 150 mm dust extraction port and efficient collection system, the machine promotes a dust-free workspace. Proper air management maintains equipment health and reduces maintenance, benefiting operators by providing better visibility and working conditions during extended production runs.

FAQs of Two Head Wide Belt Sanding Machine:

Q: How can I adjust the sanding thickness for different workpieces?

A: The machine is engineered to handle a workpiece thickness range from 3 mm to 100 mm. Thickness can be adjusted via the feed table and control settings, allowing for precise calibration based on the projects requirements.Q: What types of materials can this wide belt sanding machine process?

A: This model is ideal for sanding wood panels and furniture components. Its robust construction makes it well-suited for heavy-duty industrial use, accommodating a variety of hardwood and engineered wood surfaces.Q: When should I use both drum and pad heads during sanding?

A: The drum head excels in aggressive material removal, while the pad head provides finer finishing. Using both heads sequentially ensures smooth, uniform surfacesbegin with the drum for rough sanding, then follow with the pad for finishing.Q: Where should the dust extraction system be connected?

A: The sanding machine features a 150 mm diameter dust extraction port. Connect a compatible industrial dust collector here to remove sanding debris, maintaining cleanliness and prolonging machine life.Q: What is the process for routine maintenance of the wide belt sanding machine?

A: Routine maintenance includes inspecting sanding belts, checking belt tension, cleaning dust extraction components, and lubricating moving parts. These actions help ensure efficient operation and prevent premature wear.Q: How does the conveyor speed impact sanding results?

A: With adjustable conveyor speeds from 5 to 25 m/min, slower speeds offer more thorough sanding while higher speeds boost productivity. Select a suitable speed based on the type and condition of the material for optimal surface results.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Plywood Making Machines' category

Send Inquiry

Send Inquiry Send SMS

Send SMS