Welcome to Our Company

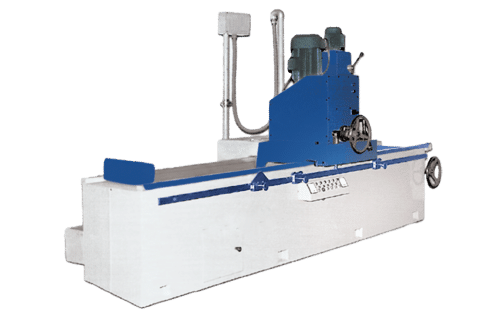

PEELING KNIFE GRINDER MACHINE (2800MM)

Product Details:

- Type Peeling Knife Grinder Machine

- Material MS (Mild Steel)

- Capacity Up to 3 Peeling Knives

- Computerized No

- Automatic Grade Semi-Automatic

- Power 7.5 HP

- Voltage 415V, 50Hz

- Click to View more

X

PEELING KNIFE GRINDER MACHINE (2800MM) Price And Quantity

- 1 Box

PEELING KNIFE GRINDER MACHINE (2800MM) Product Specifications

- Peeling Knife Grinder Machine

- No

- 7.5 HP

- 415V, 50Hz

- Green

- Semi-Automatic

- 3500 mm x 1500 mm x 1600 mm

- Up to 3 Peeling Knives

- MS (Mild Steel)

- Approx. 3000 kg

PEELING KNIFE GRINDER MACHINE (2800MM) Trade Information

- 100 Box Per Month

- 1 Months

Product Description

Specifications :

|

MODEL |

KI-KG-2800 |

|

Maximum Grinding Length |

2800 mm |

|

Grinding carriage speed |

15m/min |

|

Chuck Turning Angle |

0-90 |

|

Maximum Work-piece Height |

150 mm |

|

Grinding Wheel Speed |

1440 rpm |

|

Grinding Wheel Motor |

7.5 H.P. |

|

Total Power Required |

8.5 H.P. |

All specifications, dimensions & design characteristic are subject to change without prior notice.

Robust Construction and Design

The machine boasts a solid, heavy-duty welded mild steel frame, ensuring long service life and exceptional stability during operation. Its paint-coated surface finish not only adds to its aesthetic but also protects against corrosion, making it ideal for continuous industrial use.

Efficient Sharpening with Advanced Features

Fitted with a 350 mm grinding wheel and automatic knife movement, this grinder streamlines the sharpening process for peeling knives. Water cooling provides optimal temperature control during grinding, while variable speed settings allow for fine-tuned adjustments based on specific knife types and workloads.

User-Friendly and High Capacity

Designed for semi-automatic operation, the machine accommodates up to three peeling knives simultaneously, reducing downtime and boosting productivity. The intuitive controls and robust build enable operators to achieve precise grinding results with minimal effort, making it a valuable asset for the plywood industry.

FAQs of PEELING KNIFE GRINDER MACHINE (2800MM):

Q: How is the sharpening process carried out on this peeling knife grinder machine?

A: The sharpening process involves securely placing the peeling knife onto the machines bed. The automatic feed mechanism moves the knife under the 350 mm grinding wheel, which smooths and sharpens the edge. Water cooling maintains an optimal temperature throughout the grinding process, ensuring an even finish.Q: What types of knives can be sharpened using this machine?

A: This machine is designed specifically for sharpening and grinding peeling knives up to 2800 mm in length, which are commonly used in the plywood manufacturing industry. It can handle up to three knives at once, improving efficiency for high-volume operations.Q: When should the grinding wheel be replaced or maintained?

A: The grinding wheel should be checked regularly for wear and tear. Replacement or dressing is recommended when the wheel becomes uneven or less effective at sharpening, typically after several extended sharpening cycles or depending on the intensity of use.Q: Where can this peeling knife grinder machine be installed?

A: The machine can be installed in plywood production facilities, woodworking plants, and tool maintenance workshops. It is suitable for both large-scale manufacturing environments and specialized knife sharpening stations in India.Q: What is the benefit of the water cooling system in this machine?

A: The integrated water cooling system prevents overheating of the knife and grinding wheel during operation. This not only helps maintain the integrity of the knifes edge but also prolongs the life of the grinding wheel, ensuring consistent and safe grinding results.Q: How does the automatic feed mechanism improve the grinding process?

A: The automatic knife movement ensures uniform grinding by steadily guiding the knife across the wheel. This reduces manual intervention, enables precise sharpening, and helps maintain a consistent edge profile along the entire length of the knife.Q: What are the advantages of using a semi-automatic, heavy-duty knife grinder for the plywood industry?

A: A semi-automatic, heavy-duty grinder increases productivity by allowing multiple knives to be sharpened simultaneously and minimizes downtime between cycles. Its sturdy build ensures dependable operation, while user-friendly controls optimize workflow and safety for industrial applications.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Veneer Section' category

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free