Welcome to Our Company

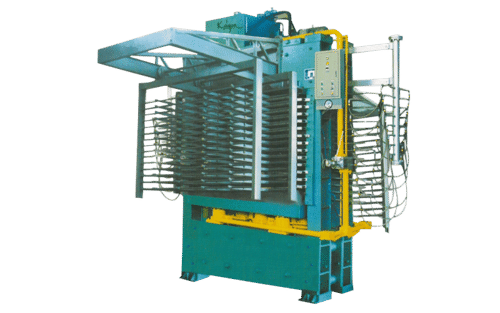

LONGITUDINAL VENEER SPLICER (KI-1250)

Product Details:

- Type Longitudinal Veneer Splicer

- Material Steel

- Capacity Approx. 1500 mm/min

- Computerized Yes

- Automatic Grade Automatic

- Power 3.7 kW

- Voltage 380 V / 50 Hz

- Click to View more

X

LONGITUDINAL VENEER SPLICER (KI-1250) Price And Quantity

- 1 Box

- 80 dB

- PLC with Touchscreen

- 350 mm

- 1 Person

- Emergency Stop, Safety Shielding

- 1250 mm

- Integrated Roller

- 0.3 mm - 2.5 mm

- Electric Heating

- Automatic Conveyor

LONGITUDINAL VENEER SPLICER (KI-1250) Product Specifications

- Approx. 1500 mm/min

- 1000 kg

- 0.6 MPa

- Automatic

- 380 V / 50 Hz

- 3.7 kW

- Steel

- Yes

- 3150 mm x 1400 mm x 1700 mm

- Longitudinal Veneer Splicer

- Blue & Grey

- 80 dB

- PLC with Touchscreen

- 350 mm

- 1 Person

- Emergency Stop, Safety Shielding

- 1250 mm

- Integrated Roller

- 0.3 mm - 2.5 mm

- Electric Heating

- Automatic Conveyor

LONGITUDINAL VENEER SPLICER (KI-1250) Trade Information

- 100 Box Per Month

- 1 Months

Product Description

Specifications:

| MODEL | KI-1250 PLUS |

| Throat Clearance | 1250 mm |

| Veneer Thickness | 0.4-1.5 (4*) mm approx. |

| Width of Veneer Strips | from 45 mm |

| Min. length of Veneer Strips | 350 mm |

| Glue Type for pre-glueing | Urea and PVA |

| Glue Type for integr. glueing | Urea |

| Feed Speed | 10-40 m/min approx. |

| Heating Temperature | 230o C upto |

| Length of Heating Area | 1250 mm |

| Total Connected Load | 7.4 Kw |

| Power Consumption | 6.4 KVA approx. |

| Air Consumption | 5 Nl/min. |

| Compressed Air Pressure | 6-8 bar |

All specifications, dimensions & design characteristic are subject to change without prior notice.

Precision Splicing Made Simple

The KI-1250 Longitudinal Veneer Splicer streamlines your veneer joining operations with its advanced PLC touchscreen controls and automatic conveyor system. Its robust design supports consistent splicing of veneer sheets, ensuring minimal waste and exceptional joint integrity for furniture or woodworking applications. The electric heating system provides reliable adhesion, while integrated safety features keep the operator secure.

Efficient and Automated Production

Boasting an impressive speed of approximately 1500 mm per minute, the KI-1250 allows manufacturers to scale production easily. Its automatic feeding and computerized controls reduce manual interventions while a single operator manages the entire process. From exporting large volumes to supplying precise sheets for local craftsmanship, its built for practical utility in Indian market conditions.

FAQs of LONGITUDINAL VENEER SPLICER (KI-1250):

Q: How does the KI-1250 Longitudinal Veneer Splicer operate for joining veneer sheets?

A: This splicer uses an automatic conveyor to feed veneer sheets into the splicing area, where an integrated roller applies glue. Electric heating ensures strong adhesion, and a PLC touchscreen controls the splicing operations. The entire process is managed by one operator for efficient workflow.Q: What materials and thicknesses can be processed with the KI-1250?

A: The machine is constructed from durable steel and accommodates veneer sheets with thicknesses ranging from 0.3 mm to 2.5 mm. It can handle a working width of up to 1250 mm and splices lengths as short as 350 mm.Q: When is the KI-1250 most suitable for use in manufacturing?

A: The KI-1250 is ideal for both large-scale and artisanal woodworking environments where reliable, high-speed veneer splicing is needed. It is especially beneficial for manufacturers, exporters, suppliers, and traders seeking consistent production quality.Q: Where can the KI-1250 be installed and operated?

A: Designed for industrial settings, the KI-1250 fits in factories, workshops, or production facilities across India. Its compact design (3150 mm x 1400 mm x 1700 mm) enables installation in various locations with access to 380 V / 50 Hz power and 0.6 MPa compressed air.Q: What process advantages does the integrated roller glue applicator offer?

A: The integrated roller ensures even and precise glue application across the veneers surface, resulting in stronger bonds and higher product quality. Combined with electric heating, it minimizes adhesive waste and improves overall efficiency.Q: Is the machine safe for operators to handle during daily use?

A: Yes, the KI-1250 features a safety shielding, emergency stop function, and noise level 80 dB, ensuring a secure and comfortable working environment. The system requires only one trained operator for full operation.Q: What are the main benefits of using the KI-1250 for veneer splicing?

A: Key benefits include automated production, reduced labor, high output speed (1500 mm/min), consistent splicing quality, computerized controls, and robust safety features. These help optimize manufacturing productivity while maintaining high quality standards.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Plywood Making Machines' category

Send Inquiry

Send Inquiry Send SMS

Send SMS