Welcome to Our Company

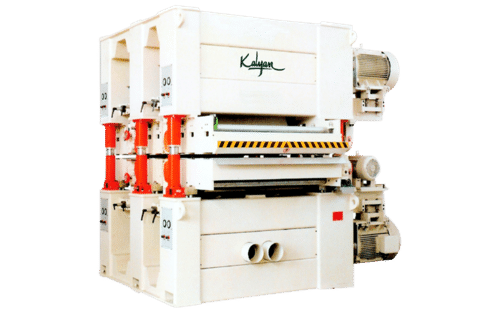

FOUR ROLLER GLUE SPREADER MACHINE

Product Details:

- Type Four Roller Glue Spreader Machine

- Material Mild Steel Body with High-Quality Rubber Rollers

- Capacity Up to 700 mm (Roller Working Width)

- Computerized No

- Automatic Grade Semi-Automatic

- Power 1.5 HP

- Voltage 220-240 V, Single Phase

- Click to View more

X

FOUR ROLLER GLUE SPREADER MACHINE Price And Quantity

- 1 Unit

FOUR ROLLER GLUE SPREADER MACHINE Product Specifications

- 1450 x 900 x 1200 mm

- 220-240 V, Single Phase

- Approx. 350 kg

- No

- Blue & Grey

- Up to 700 mm (Roller Working Width)

- 1.5 HP

- Four Roller Glue Spreader Machine

- Semi-Automatic

- Mild Steel Body with High-Quality Rubber Rollers

FOUR ROLLER GLUE SPREADER MACHINE Trade Information

- 10 Unit Per Month

- 7 Days

Product Description

Experience trending innovation with the First-string FOUR ROLLER GLUE SPREADER MACHINE, engineered for radiant, double-sided glue application. This cost-effective unit boasts four 130 mm hard chrome-plated steel rollers, providing uncommon precision in glue layer adjustment. Its heavy-duty frame, protective guards, and emergency stop guarantee safety, while the manual feed and motorized operation offer dynamic workflow. Suitable for plywood, veneer, MDF, and particle board, it handles up to 700 mm width, making it ideal for woodworking and furniture manufacturing. Order now to enhance productivity and achieve impeccable results!

Advantages & Application Media

The FOUR ROLLER GLUE SPREADER MACHINE delivers uniform glue spreading, significantly boosting efficiency for wood panels. Its adaptable feed speed and precise thickness adjustment are perfect for a variety of substrates, including plywood, MDF, veneer, and particle board. Used for both woodworking and furniture manufacturing, it ensures radiant, consistent bonding on double sides. The machines robust structure and simplicity of operation help maintain superior production standards in vibrant industrial settings.

Export Market, Sample Policy & Availability

Highly acclaimed in export markets, the FOUR ROLLER GLUE SPREADER MACHINE boasts competitive rates and low expenditure on maintenance. Sample units are available on request, enabling clients to evaluate performance and freight options before committing to bulk orders. Exporter, importer, manufacturer, supplier, and trader networks in India rely on this first-string machine for radiantly smooth lamination processes across international markets, with flexible sample policies to support purchasing decisions.

Advantages & Application Media

The FOUR ROLLER GLUE SPREADER MACHINE delivers uniform glue spreading, significantly boosting efficiency for wood panels. Its adaptable feed speed and precise thickness adjustment are perfect for a variety of substrates, including plywood, MDF, veneer, and particle board. Used for both woodworking and furniture manufacturing, it ensures radiant, consistent bonding on double sides. The machines robust structure and simplicity of operation help maintain superior production standards in vibrant industrial settings.

Export Market, Sample Policy & Availability

Highly acclaimed in export markets, the FOUR ROLLER GLUE SPREADER MACHINE boasts competitive rates and low expenditure on maintenance. Sample units are available on request, enabling clients to evaluate performance and freight options before committing to bulk orders. Exporter, importer, manufacturer, supplier, and trader networks in India rely on this first-string machine for radiantly smooth lamination processes across international markets, with flexible sample policies to support purchasing decisions.

FAQs of FOUR ROLLER GLUE SPREADER MACHINE:

Q: How does the FOUR ROLLER GLUE SPREADER MACHINE benefit woodworking production?

A: The machine enhances productivity by applying glue evenly and consistently on both sides of wood panels, resulting in better bonding and reduced wastage during manufacturing.Q: What materials can be processed with this glue spreader?

A: It is suitable for plywood, veneer, MDF, and particle board, making it versatile for various woodworking and furniture manufacturing applications.Q: Where is this machine commonly used?

A: The FOUR ROLLER GLUE SPREADER MACHINE is primarily used in woodworking shops, furniture production units, and manufacturing facilities dealing with panel materials.Q: When can a sample of the machine be requested?

A: Samples can be requested at any stage of inquiry, with flexible policies allowing businesses to experience the machines capabilities before large orders.Q: What safety features are included in the machine?

A: Key safety features include emergency stop switches and protective guards built into the heavy-duty fabricated frame, ensuring secure and safe operation.Q: How is the glue layer thickness adjusted during operation?

A: Thickness adjustment is handled manually, allowing precise control according to the requirements of each project and substrate.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Pressing Section' category

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free