Welcome to Our Company

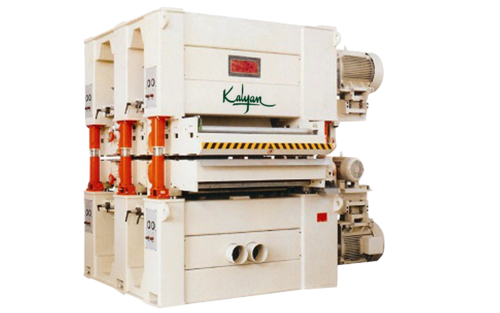

FOUR HEAD TOP AND BOTTOM WIDE BELT SANDING MACHINE (KID-1300-R-R )

Product Details:

- Type Top and Bottom Wide Belt Sanding Machine

- Material Stainless Steel, Mild Steel

- Capacity Continuous Operation

- Computerized No

- Automatic Grade Fully Automatic

- Power 54 kW

- Voltage 380V/415V, 3 Phase

- Click to View more

X

FOUR HEAD TOP AND BOTTOM WIDE BELT SANDING MACHINE (KID-1300-R-R ) Price And Quantity

- 1 , , Box

FOUR HEAD TOP AND BOTTOM WIDE BELT SANDING MACHINE (KID-1300-R-R ) Product Specifications

- No

- 0.6 MPa

- 3200 kg

- 54 kW

- Fully Automatic

- Stainless Steel, Mild Steel

- 380V/415V, 3 Phase

- 3300 x 2150 x 2300 mm

- Continuous Operation

- White & Blue

- Top and Bottom Wide Belt Sanding Machine

FOUR HEAD TOP AND BOTTOM WIDE BELT SANDING MACHINE (KID-1300-R-R ) Trade Information

- 100 , , Box Per Month

- 1 Months

Product Description

Specification:

|

MODEL |

KID-1300-R-R |

|

Working width |

1300 mm |

|

Working thickness |

5-100 mm |

|

Working length |

> 500 mm |

|

First Sanding belt linear speed |

28 mm/s |

|

Second Sanding belt linear speed |

28 mm/s |

|

Precision |

0.08 mm |

|

Feed speed |

8-40 m/min |

|

Conveyor motor (inverter control) |

15 Kw |

|

First Top & Bottom Head Motor |

75 / 90 kw x 2 nos. |

|

Second Top & Bottom Head Motor |

75 / 90 kw x 2 nos. |

|

PLC |

Siemens |

|

Touch Screen |

Siemens |

|

Touch Screen |

Hanging Type |

|

All major Electricals |

Siemens |

|

Bearing |

FAG / SKF |

|

Work pressure |

0.55 Mpa |

|

Air flow quantity |

60000 m3/h |

|

Wind Speed of dust outlet |

25 m/s |

|

Sanding Belt size |

3000x1350 mm |

|

Net weight |

32000 Kgs. |

Efficient Double-Sided Sanding in One Pass

The KID-1300-R-R sanding machine streamlines board processing by sanding both top and bottom surfaces simultaneously. This four-head configuration increases productivity and ensures a precise finish. Designed for a working width up to 1300 mm and thicknesses from 2 to 100 mm, it caters to a wide range of wood panels and components, making it a versatile choice for manufacturers.

Advanced Digital and Safety Controls

Equipped with a digital/PLC control panel, this sanding machine delivers precise adjustments and intuitive operation. Operators benefit from overload and emergency stop protection, ensuring both machine and user safety during continuous operation. The automatic grade further simplifies usage for consistent, high-quality results.

Industrial-Grade Build for Diverse Applications

Manufactured using stainless steel and mild steel, the KID-1300-R-R is robust and suitable for continuous heavy-duty tasks. Its design caters to woodworking, panel processing, door manufacturing, and more. The six dust extraction ports maintain a cleaner, safer work environment, supporting high-capacity and professional needs.

FAQs of FOUR HEAD TOP AND BOTTOM WIDE BELT SANDING MACHINE (KID-1300-R-R ):

Q: How does the FOUR HEAD TOP AND BOTTOM WIDE BELT SANDING MACHINE improve efficiency in sanding operations?

A: This machine allows simultaneous sanding of both the top and bottom surfaces of boards in one pass, reducing processing time and improving overall productivity for manufacturers.Q: What materials and applications is the KID-1300-R-R suitable for?

A: It is designed for woodworking, panel processing, and door manufacturing, capable of handling various board materials using high-quality stainless and mild steel construction for durability in continuous operation.Q: When should I use this machine in my production line?

A: The KID-1300-R-R is ideal for use whenever you require precise calibration and uniform sanding of both sides of panels, especially in medium to high-volume manufacturing settings.Q: Where should the machine be installed for optimal performance?

A: Install the sanding machine in a well-ventilated workshop with provisions for dust extraction connections (six 125 mm ports) and sufficient space for its dimensions (3300 x 2150 x 2300 mm). It requires 380V/415V, 3-phase electrical supply and 0.6 MPa air pressure.Q: What is the typical process for using this wide belt sanding machine?

A: Boards are fed into the machine, where four sanding heads (two top, two bottom) operate at adjustable feed speeds (630 m/min) to sand and calibrate both sides simultaneously. The PLC control panel enables precise parameter adjustments.Q: What are the main benefits of the KID-1300-R-R for industrial manufacturers?

A: This machine offers rapid, simultaneous dual-sided sanding, robust safety features, low noise levels (<85 dB(A)), and minimal manual intervention, making it reliable for continuous use in demanding production environments.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Pressing Section' category

Send Inquiry

Send Inquiry Send SMS

Send SMS