Welcome to Our Company

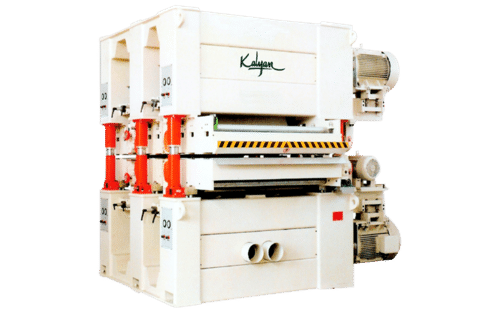

FOUR HEAD TOP AND BOTTOM / DOUBLE DECK WIDE BELT SANDING MACHINE (KID-1300-R-RP)

Product Details:

- Type Wide Belt Sanding Machine

- Material Heavy Duty Steel

- Capacity 1300mm Working Width

- Computerized No

- Automatic Grade Automatic

- Power 53.5 kW

- Voltage 380V / 50Hz

- Click to View more

X

FOUR HEAD TOP AND BOTTOM / DOUBLE DECK WIDE BELT SANDING MACHINE (KID-1300-R-RP) Price And Quantity

- 1 Box

FOUR HEAD TOP AND BOTTOM / DOUBLE DECK WIDE BELT SANDING MACHINE (KID-1300-R-RP) Product Specifications

- Grey and Blue

- Wide Belt Sanding Machine

- No

- Automatic

- 5000 kg

- 2600 x 2700 x 2200 mm

- Heavy Duty Steel

- 1300mm Working Width

- 0.6 MPa

- 53.5 kW

- 380V / 50Hz

- Four Heads

FOUR HEAD TOP AND BOTTOM / DOUBLE DECK WIDE BELT SANDING MACHINE (KID-1300-R-RP) Trade Information

- 100 Box Per Month

- 1 Months

Product Description

Specification:

|

Working width |

1300mm |

|

Working thickness |

5-100mm |

|

Working length |

> 500mm |

|

First sanding belt speed |

28m/s |

|

Second sanding belt speed |

26m/s |

|

Feed speed |

8-40m/min |

|

1st Top & Bottom Head Motor |

75 kw x 2 Nos. |

|

2nd Top & Bottom Head Motor |

55 kw x 2 nos. |

|

Work pressure |

0.55Mpa |

|

Air flow quantity |

32000m3/h |

|

Sanding Belt size |

3300x1350/3320x1350mm |

|

Overall size |

3450x3500x3150mm |

|

Net weight |

35000kgs |

All specifications, dimensions & design characteristic are subject to change without prior notice.

Comprehensive Sanding for Top and Bottom Surfaces

This machine features a unique double deck system with four sanding heads, enabling simultaneous sanding of both the top and bottom surfaces. The configuration ensures uniform finish quality, enhancing productivity and reducing processing time for a variety of wood-based materials including MDF and plywood.

High-Performance Design and Robust Construction

Manufactured with heavy-duty steel, the KID-1300-R-RP delivers enduring performance and stability even under continuous industrial use. Its advanced PLC control panel provides intuitive machine operation and precise adjustment, supporting automated production lines and customized finishing requirements.

Advanced Safety and Maintenance Features

Safety is paramount, with features like an emergency stop button and overload protection keeping operators secure. The machine also boasts low noise operation and efficient dust extraction through four 150 mm ports, maintaining a safer, cleaner work environment. Routine maintenance is straightforward, adding to machine reliability.

FAQs of FOUR HEAD TOP AND BOTTOM / DOUBLE DECK WIDE BELT SANDING MACHINE (KID-1300-R-RP):

Q: How does the double deck system improve the sanding process?

A: The double deck system enables simultaneous sanding of both the top and bottom surfaces of your workpiece, significantly enhancing processing speed and surface consistency. This results in higher throughput while maintaining a uniform finish across materials such as wood, plywood, and MDF.Q: What materials and thicknesses can the KID-1300-R-RP accommodate?

A: This sanding machine is suitable for wood, plywood, and MDF. It accommodates workpieces with a minimum thickness of 2.5 mm and a maximum of 100 mm, with a maximum working width of 1300 mm.Q: When is this wide belt sanding machine most beneficial in production?

A: The KID-1300-R-RP excels in high-volume, industrial settings where efficient, uniform top and bottom sanding is required. It is particularly valuable in workshops and factories focusing on furniture manufacturing, panel production, and finishing processes.Q: Where should this sanding machine be installed for optimal performance?

A: Install the machine in a well-ventilated industrial space with adequate power supply (380V / 50Hz) and accessible dust extraction systems. Its robust design allows placement in demanding production environments with sufficient space for operation and maintenance.Q: What is the process for operating and adjusting the feeding speed?

A: The feeding speed is adjustable between 530 m/min via the PLC control panel, allowing you to tailor settings according to material type, required finish, and production speed. Operators can easily make adjustments to optimize results for various applications.Q: How do the safety features enhance operator protection?

A: Equipped with an emergency stop and overload protection, the machine prioritizes operator safety by quickly halting operations if unsafe conditions are detected, minimizing risk during use.Q: What are the key benefits of using this wide belt sanding machine?

A: Key benefits include faster processing with simultaneous top and bottom sanding, uniform surface finishing, robust construction for durability, customizable automated controls, and reliable safety mechanisms, making it ideal for diverse wood processing needs.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Pressing Section' category

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free