Welcome to Our Company

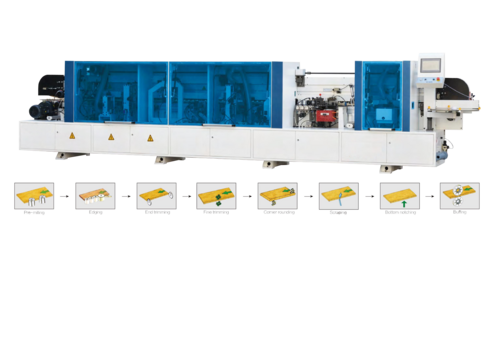

AUTOMATIC EDGE BANDING MACHINE MODEL KI6AB

Product Details:

- Product Type Automatic Edge Banding Machine

- Machine Type Edge Banding

- Machine Style Horizontal

- Capacity 10-15 m/min

- Voltage 380 V

- Power 7 kW

- Automation Fully Automatic

- Click to View more

X

AUTOMATIC EDGE BANDING MACHINE MODEL KI6AB Price And Quantity

- 1 Millimeter

AUTOMATIC EDGE BANDING MACHINE MODEL KI6AB Product Specifications

- 4300 x 900 x 1600 mm

- Yes, Heavy Duty Motor

- 10-20 m/min

- 10-15 m/min

- 1200 kg

- Horizontal

- 380 V

- Automatic Edge Banding Machine

- Edge Banding

- Fully Automatic

- 7 kW

- White & Blue

Product Description

Experience outstanding performance and unbeatable value with the AUTOMATIC EDGE BANDING MACHINE MODEL KI6AB. This fully automatic solution delivers remarkable savings for woodworking and furniture manufacturing businesses, thanks to its robust heavy-duty build and impressive efficiency. Take advantage of its noble design, designed for consistent quality and superior finishing. With features like hot melt gluing, digital touch control, fine-finishing units, and speeds up to 20 m/min, this machine is an investment in both craftsmanship and productivity. Make your production process seamless and reliable with KI6AB today.

Versatile Usage and Enhanced Features with KI6AB

The AUTOMATIC EDGE BANDING MACHINE MODEL KI6AB is engineered for horizontal edge banding across a wide 10-60 mm feeding thickness range, making it perfect for woodworking and furniture manufacturing. Packed with extra features like pre-milling, trimming, scraping, buffing, and digital touch screen controls, this machine excels in delivering seamless, professional results. Its integrated units for end cutting and fine finishing set this model apart, ensuring unmatched quality at every stage of the process.

Sample Availability and Swift Order Fulfillment

Sample requests for the AUTOMATIC EDGE BANDING MACHINE MODEL KI6AB are welcome, allowing businesses to assess its exceptional capabilities first-hand. The machine is dispatched from India's main domestic markets with secure packaging to ensure safe transit. Order processing is straightforward, and express shipping options are available for urgent requirements, ensuring you receive your KI6AB quickly and in excellent condition. Trust our efficient dispatch and packaging procedures for a smooth transaction every time.

Versatile Usage and Enhanced Features with KI6AB

The AUTOMATIC EDGE BANDING MACHINE MODEL KI6AB is engineered for horizontal edge banding across a wide 10-60 mm feeding thickness range, making it perfect for woodworking and furniture manufacturing. Packed with extra features like pre-milling, trimming, scraping, buffing, and digital touch screen controls, this machine excels in delivering seamless, professional results. Its integrated units for end cutting and fine finishing set this model apart, ensuring unmatched quality at every stage of the process.

Sample Availability and Swift Order Fulfillment

Sample requests for the AUTOMATIC EDGE BANDING MACHINE MODEL KI6AB are welcome, allowing businesses to assess its exceptional capabilities first-hand. The machine is dispatched from India's main domestic markets with secure packaging to ensure safe transit. Order processing is straightforward, and express shipping options are available for urgent requirements, ensuring you receive your KI6AB quickly and in excellent condition. Trust our efficient dispatch and packaging procedures for a smooth transaction every time.

FAQ's of AUTOMATIC EDGE BANDING MACHINE MODEL KI6AB:

Q: How does the AUTOMATIC EDGE BANDING MACHINE KI6AB improve productivity in woodworking applications?

A: The KI6AB is a fully automatic machine, featuring a heavy-duty motor, digital touch controls, and multi-stage processing units. This combination allows for continuous operation, minimal downtime, and superior finishing, boosting overall productivity in woodworking and furniture manufacturing.Q: What is the range of materials and panels that the KI6AB can handle?

A: This model is designed for edge thicknesses between 0.4 to 3 mm, with feeding thickness capabilities of 10 to 60 mm. It accommodates panel lengths as short as 120 mm and widths down to 60 mm, making it versatile for a variety of panel sizes and materials including wood and composite boards.Q: When is the ideal time to use the edge banding machine's pre-milling feature?

A: Pre-milling should be used when panels require a perfectly smooth surface before gluing the edge tape. This is especially beneficial for rough or uneven edges, ensuring strong adhesion and a professional finish during the edge banding process.Q: Where can the KI6AB be shipped and how is it packaged?

A: The KI6AB is available for dispatch to all major domestic markets in India. Each unit is carefully packaged for secure transportation, with options for express shipping to ensure timely delivery.Q: What are the main benefits of the digital touch screen control panel on the KI6AB?

A: The digital touch screen control panel offers intuitive operation, precise adjustments, and real-time monitoring, allowing operators to efficiently manage all machine functions and enhance workflow through user-friendly controls.Q: How does the machine ensure a high-quality edge finish on panels?

A: With its integrated pre-milling, trimming, end cutting, scraping, and buffing units, the KI6AB delivers consistent and fine finishing. Each panel passes through dedicated stages, ensuring the edges are precisely glued, cut, and polished for an outstanding final appearance.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

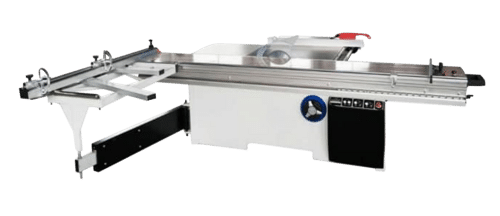

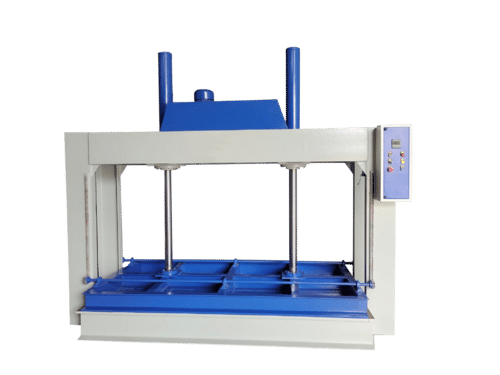

Other Products in 'Modular Furniture' category

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free