Welcome to Our Company

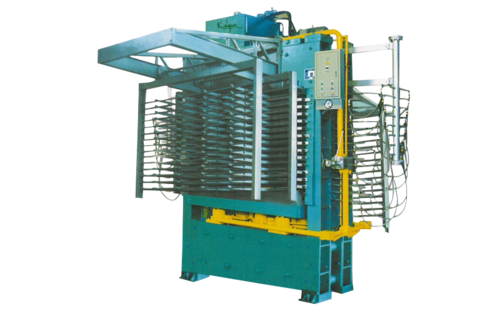

640 TONNE HYDRAULIC HOT PRESS 8' X 4'

Product Details:

- Type Hydraulic Hot Press

- Material Mild Steel

- Capacity 640 Tonne

- Computerized No

- Automatic Grade Semi-Automatic

- Power 25 HP

- Voltage 415 V

- Click to View more

X

640 TONNE HYDRAULIC HOT PRESS 8' X 4' Price And Quantity

- 1 Box

640 TONNE HYDRAULIC HOT PRESS 8' X 4' Product Specifications

- 8 ft x 4 ft (Platen Size)

- Mild Steel

- 415 V

- Blue / Grey

- 640 Tonne

- 25 HP

- 6-8 Kg/Cm

- 18000 Kg (approx)

- No

- Semi-Automatic

- Hydraulic Hot Press

640 TONNE HYDRAULIC HOT PRESS 8' X 4' Trade Information

- 100 Box Per Month

- 1 Months

Product Description

640 Tonne Hydraulic Hot Press 8'x4' (China Make)

- 15 day lights in Heavy Duty Structure having 4 Gates

- Loading and unloading unit (Auto -Hanging type)

- Hydraulic vales 'Yuken'

- Rexroth Pump (High pressure)

- Automatic power pack

- Electric control panels and Motors

- All major electricals-siemens/scheider/omron

- Motors-'CE Certified'

Technical specification

| Plate Frame with Window Opening |

| |

|

| 15 Daylight | 20 Daylight |

| Total Pressure | 650 Tonne | 650 Tonne |

| Platen Size | 2600 x1370 mm x 42+1mm | 2600 x1370 mm x 42+1mm |

| No. of Heating Platens | 16 nos. | 21 nos. |

| No. of Day Lights | 15 DL | 20 DL |

| Day Light Opening | 70 / 75 mm | 70 / 75 mm |

| No. of Rams | 8 | 8 |

| Dia of Each Ram | f200 mm | f200mm |

| Power Required with loading & unloading | 32 kw | 32 kw |

| Heating Medium | Thermic Fluid / Steam / Hot Water | |

| Frame | Fabricated out of tested MS Plates adequately reinforced to take full load. | |

All specifications, dimensions& design characteristic are subject to change without prior notice

Versatile Applications Across Industries

This hydraulic hot press accommodates a spectrum of production needs, including plywood, particle board, laminates, and moulded doors. Its high capacity and precision make it valuable for manufacturers seeking consistent and high-quality output. The machines adaptable heating options (electric, steam, thermic fluid) and programmable controls ensure it meets diverse industrial requirements seamlessly.

Built for Reliability and Safety

With an H-frame welded structure and robust alloy steel heating plates, the press guarantees longevity and operational stability. Integrated safety features, such as overload protection, emergency stop, and temperature controllers, provide peace of mind during intensive operations, ensuring the safety of both operators and equipment while maintaining production efficiency.

FAQs of 640 TONNE HYDRAULIC HOT PRESS 8 X 4:

Q: How does the adjustable cycle time of the 640 Tonne Hydraulic Hot Press benefit production?

A: The adjustable cycle time, typically set between 4 to 6 minutes, allows operators to customize pressing duration according to specific material requirements, optimizing efficiency and ensuring optimal bonding quality for products like plywood and laminates.Q: What can I manufacture with this hydraulic hot press?

A: This machine is suitable for manufacturing a wide range of products, including plywood, particle boards, laminates, and moulded doors, providing versatility for various wood-based and composite panel applications.Q: When should I use the electric, steam, or thermic fluid heating system?

A: The choice of heating system depends on operational preferences and energy availability. Electric heating offers precision and convenience, steam is suitable where a central boiler is available, and thermic fluid provides consistent high-temperature distribution, especially for large-scale operations.Q: Where is the 640 Tonne Hydraulic Hot Press most effectively utilized?

A: It is ideally suited for industrial manufacturing environments, such as woodworking factories, panel production units, and facilities specializing in composite material processing, where consistency, speed, and high pressure are essential.Q: What process ensures the safety of operators using this press?

A: Safety is enhanced through features like overload protection, an emergency stop system, and precise temperature controllers, all designed to prevent accidents and protect both the operator and equipment during high-pressure cycles.Q: How does the PLC based control panel improve operation?

A: A PLC (Programmable Logic Controller) panel allows for more precise control over pressing parameters, cycle times, and safety settings, resulting in increased accuracy, easier repeatability of processes, and reduced manual intervention.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Plywood Making Machines' category

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free