Welcome to Our Company

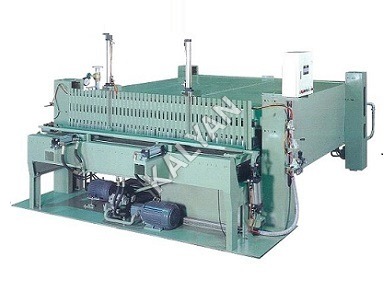

Semi Automatic Block Board Composer

Product Details:

- Type Block Board Composer

- Capacity 70kgs/hr Kg/hr

- Automatic Grade Semi-Automatic

- Power 10.5 kw Watt (w)

- Weight Approx. 7,000 kgs Kilograms (kg)

- Color Green

- Click to View more

X

Semi Automatic Block Board Composer Price And Quantity

- 1 Box

Semi Automatic Block Board Composer Product Specifications

- 70kgs/hr Kg/hr

- 10.5 kw Watt (w)

- Green

- Semi-Automatic

- Approx. 7,000 kgs Kilograms (kg)

- Block Board Composer

Semi Automatic Block Board Composer Trade Information

- 100 Box Per Month

- 1 Months

Product Description

Specifications

MODEL | SM-HAN-8 |

Length of Product | 1880-2,514mm(6,7,8) |

Strip Thickness | 8-25mm |

Strip Width | 35-50mm / 30-50 mm |

Motor for oil pump | 10hpx4p, 1 set |

Motor for circular saw | 5hpx2p, 1 set |

Power | 10.5 kw |

Stream Pressure | 3-7 kgs/cm2 |

Compressed Air | 5.0kgs/cm2, necessary |

Max. pushing speed | 45 strokes/min. |

Hydraulic Control System | 1 set |

Pneumatic Control System | 1 set |

Electric Control System | 1 set |

Upper steam heaters | 130x130x4,000mmx17 pcs. |

Lower steam heaters | 130x130x3,715mmx17 pcs. |

Consumption | 70kgs/hr |

Machine Size | 5,420x3,260x2,050mm |

Net weight | Approx. 7,000 kgs |

Gross weight | Approx. 7,500 kgs |

All specifications, dimensions & design characteristic are subject to change without prior notice.

Efficient Block Board Composing

This semi automatic composer enables manufacturers to assemble and press block boards with accuracy and speed. Its 70 kg/hr capacity makes it suitable for medium to large-scale operations, ensuring consistent productivity and high-quality results. The substantial build enhances stability and reduces vibration during operation.

Versatile Applications across India

The machine is available for exporters, importers, manufacturers, suppliers, and traders throughout India. Its design appeals to businesses seeking optimization in their block board production processes, offering an optimal balance between automation and manual control.

FAQs of Semi Automatic Block Board Composer:

Q: How does the semi automatic block board composer function during operation?

A: It utilizes a semi automatic mechanism to assemble and press wood strips into block boards. Operators load the raw materials, after which the machine aligns and composes the boards, followed by pressing to ensure strength and uniformity.Q: What are the main benefits of using this block board composer?

A: Users benefit from increased efficiency, consistent board quality, and reduced labor. The machines semi-automatic controls allow for streamlined operation, minimizing errors and material wastage while enhancing production rates.Q: When is this machine typically used in the manufacturing process?

A: It is employed during the assembly and pressing stage of block board production, after cutting and sizing the wood strips but before finishing and packaging.Q: Where can the semi automatic block board composer be sourced in India?

A: The equipment is available from exporters, importers, manufacturers, suppliers, and traders throughout India, making it accessible for businesses nationwide seeking reliable block board production machinery.Q: What is the process for composing block boards using this machine?

A: Operators arrange prepared wood strips into the composer, which then aligns, composes, and presses the boards into a flat, sturdy sheet. The process ensures tight bonding and dimensional accuracy.Q: How does the machines capacity and power specifications support industrial usage?

A: With a capacity of 70 kg/hr and power usage of 10.5 kW, the composer supports continuous operation and steady output for medium and large manufacturing facilities, ensuring consistent results and meeting production targets.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

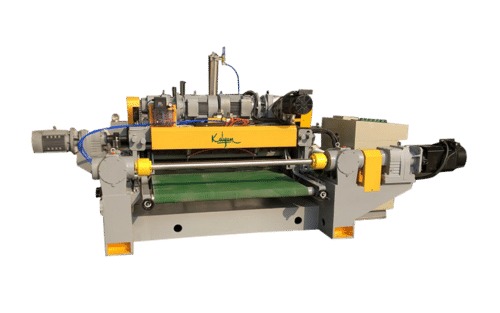

Other Products in 'Plywood Making Machines' category

Send Inquiry

Send Inquiry Send SMS

Send SMS