Welcome to Our Company

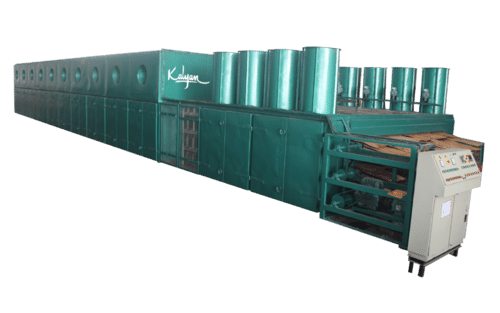

JET VENTILATED ROLLER TRACK VENEER DRYER 10 SECTION 3 DECKS (15')

1.0 INR/Box

Product Details:

- Type Jet Ventilated Roller Track Veneer Dryer

- Material High-grade Carbon Steel, Stainless Steel

- Capacity Up to 3,000 m per day

- Computerized No

- Automatic Grade Semi-Automatic

- Power 120 kW

- Voltage 415 V, 3 Phase

- Click to View more

X

JET VENTILATED ROLLER TRACK VENEER DRYER 10 SECTION 3 DECKS (15') Price And Quantity

- 1.0 INR/Box

- 1 Box

JET VENTILATED ROLLER TRACK VENEER DRYER 10 SECTION 3 DECKS (15') Product Specifications

- Up to 3,000 m per day

- Industrial Grey

- 415 V, 3 Phase

- High-grade Carbon Steel, Stainless Steel

- No

- Jet Ventilated Roller Track Veneer Dryer

- Approx. 35,000 kg

- Semi-Automatic

- 120 kW

- 15,000 mm x 5,800 mm x 4,200 mm

- 0.6-0.8 MPa

JET VENTILATED ROLLER TRACK VENEER DRYER 10 SECTION 3 DECKS (15') Trade Information

- 100 Box Per Month

- 1 Months

- South India

Product Description

Experience the splendiferous performance of the JET VENTILATED ROLLER TRACK VENEER DRYER 10 SECTION 3 DECKS (15). Utilise this glorious solution for veneer drying, crafted from ineffable quality carbon and stainless steel for enhanced durability. With 10 ineffable sections and 3 robust decks, this semi-automatic marvel boasts thermal oil/steam heating, high-capacity drying up to 3,000 m daily, and precise control options. Buy online now to secure value and reliability for your plywood and laminated veneer lumber production. Offer available for global tradersinstallation by manufacturer!

Exceptional Efficiency and Versatility for Veneer Drying

JET VENTILATED ROLLER TRACK VENEER DRYER 10 SECTION 3 DECKS (15) delivers competitive advantages through its powerful jet ventilation system, splendiferous heat insulation, and flexible manual control. This machine processes a wide veneer thickness and width range, adjusting to varied production requirements. Perfect for both general and specific applications, its ideal for plywood manufacturing and laminated veneer lumber. Its semi-automatic operation ensures reliability, meeting ISO 9001:2015 standards for global users.

Reliable Supply, Export Markets, and Packing Excellence

With consistently high supply ability, our dryer reaches leading international markets. Packing & Dispatch are handled with meticulous attention, utilizing robust packaging for safe worldwide shipment. Logistics are optimized for timely delivery, ensuring customers benefit from our offer of quality and efficiency. Each machine is supplied in industrial-grade packaging, supported by manufacturer-led on-site installation, further enhancing confidence for exporters, importers, and traders across India and beyond.

Exceptional Efficiency and Versatility for Veneer Drying

JET VENTILATED ROLLER TRACK VENEER DRYER 10 SECTION 3 DECKS (15) delivers competitive advantages through its powerful jet ventilation system, splendiferous heat insulation, and flexible manual control. This machine processes a wide veneer thickness and width range, adjusting to varied production requirements. Perfect for both general and specific applications, its ideal for plywood manufacturing and laminated veneer lumber. Its semi-automatic operation ensures reliability, meeting ISO 9001:2015 standards for global users.

Reliable Supply, Export Markets, and Packing Excellence

With consistently high supply ability, our dryer reaches leading international markets. Packing & Dispatch are handled with meticulous attention, utilizing robust packaging for safe worldwide shipment. Logistics are optimized for timely delivery, ensuring customers benefit from our offer of quality and efficiency. Each machine is supplied in industrial-grade packaging, supported by manufacturer-led on-site installation, further enhancing confidence for exporters, importers, and traders across India and beyond.

FAQs of JET VENTILATED ROLLER TRACK VENEER DRYER 10 SECTION 3 DECKS (15):

Q: How does the jet ventilation system enhance veneer drying efficiency?

A: The high-pressure jet ventilation system ensures even heat distribution and accelerated drying, resulting in uniform moisture content and minimised energy consumption for various veneer types.Q: What materials can be processed using this veneer dryer?

A: This dryer is ideal for processing veneers used in plywood and laminated veneer lumber, accommodating a thickness range from 0.5 mm to 4 mm and a width between 600 mm and 1,300 mm.Q: Where can installation of the machine be arranged?

A: On-site installation is offered by the manufacturer, ensuring professional setup and calibration at your facility, whether in India or exported internationally.Q: What is the supply process and availability for this dryer?

A: Supply is reliable, with products dispatched using secure packaging to reach global clients efficiently through optimized logistics channels and manufacturer-led coordination.Q: What benefits can users expect from this veneer dryer?

A: Users benefit from high daily capacity (up to 3,000 m), energy-efficient heat insulation, precise manual control, SPLENDIFEROUS build quality, and compliance with ISO standards for quality assurance.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Veneer Section' category

Send Inquiry

Send Inquiry Send SMS

Send SMS